798983

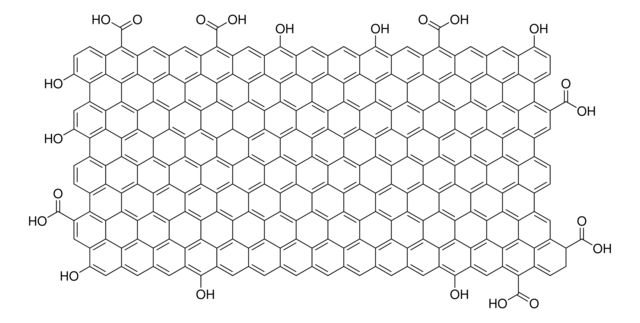

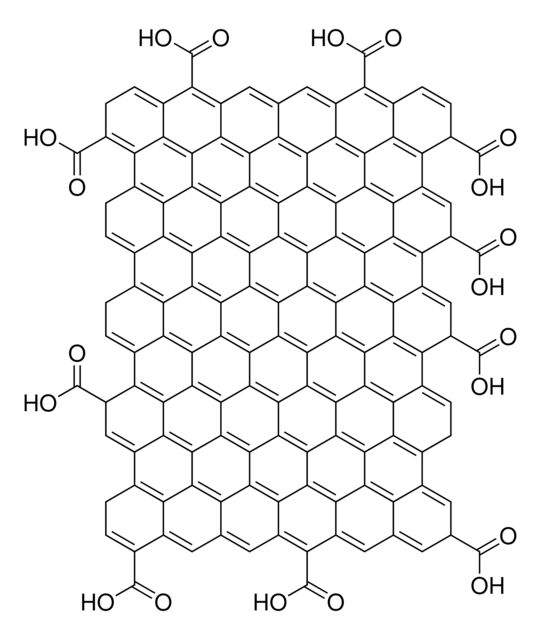

Graphene ink

for screen printing, with ethyl cellulose in terpineol, screen printable

Manufacturer: Sigma Aldrich

Synonym(S): Graphene ink, conductive ink

Select a Size

| Pack Size | SKU | Availability | Price |

|---|---|---|---|

| 10 ML | 798983-10-ML | In Stock | ₹ 43,190.10 |

798983 - 10 ML

In Stock

Quantity

1

Base Price: ₹ 43,190.10

GST (18%): ₹ 7,774.218

Total Price: ₹ 50,964.318

Quality Level

100

form

liquid

composition

Solid content, 13-20%

greener alternative product characteristics

Design for Energy EfficiencyLearn more about the Principles of Green Chemistry.

sustainability

Greener Alternative Product

resistivity

0.003-0.008 Ω-cm, thermally annealed 300 °C for 30 minutes, film thickness >100 nm, 25 °C

particle size

≤3 μm

viscosity

5-50 Pa.s(25 °C) (shear viscosity at 10 s-1)

bp

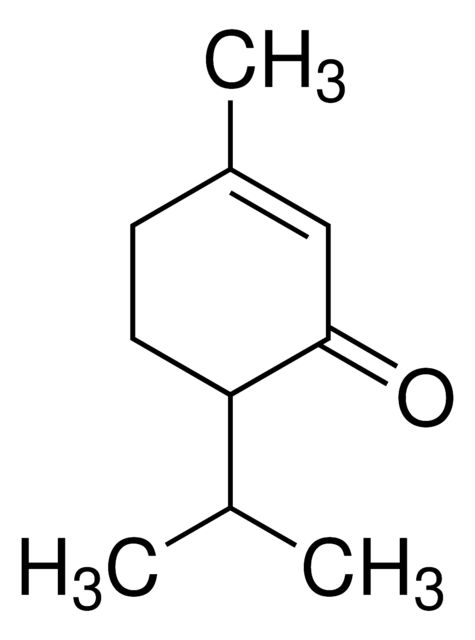

213-218 °C (Terpineol)

density

0.9-1.1 g/mL at 25 °C

Description

- General description: We are committed to bringing you Greener Alternative Products, which adhere to one or more of The 12 Principles of Greener Chemistry. This product belongs to Enabling category of greener alternatives thus aligns with "Design for energy efficency". 3D printable inks help to design and print more complex designs with minimum waste and it is environmentally friendly. Click here for more information.

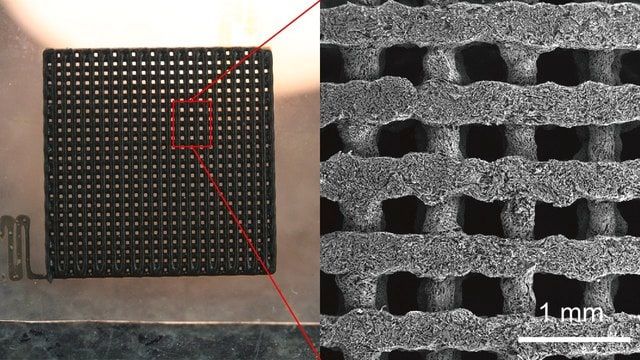

- Application: Graphene dispersion formulated for screen printing.Curing Condition: 250-350 °C, 20-30 minThe printed films are generally too thick for photonic annealing, so the substrate will need to be compatible with the thermal curing conditions (typically 250-300 C for 30 minutes works well for most applications). Suggested substrates include Si/SiO2 and polyimide.

- Legal Information: Sold under Material Transfer Agreement with Mark Hersam group at Northwestern University.

SAFETY INFORMATION

Pictograms

Signal Word

Warning

Hazard Statements

Precautionary Statements

P264 - P280 - P302 + P352 - P305 + P351 + P338 - P332 + P313 - P337 + P313

Hazard Classifications

Eye Irrit. 2 - Skin Irrit. 2

WGK

WGK 3

Compare Similar Items

Show Difference

Quality Level: 100

form: liquid

composition: Solid content, 13-20%

greener alternative product characteristics: Design for Energy EfficiencyLearn more about the Principles of Green Chemistry.

sustainability: Greener Alternative Product

resistivity: 0.003-0.008 Ω-cm, thermally annealed 300 °C for 30 minutes, film thickness >100 nm, 25 °C

particle size: ≤3 μm

viscosity: 5-50 Pa.s(25 °C) (shear viscosity at 10 s-1)

bp: 213-218 °C (Terpineol)

density: 0.9-1.1 g/mL at 25 °C

Quality Level:

100

form:

liquid

composition:

Solid content, 13-20%

greener alternative product characteristics:

Design for Energy EfficiencyLearn more about the Principles of Green Chemistry.

sustainability:

Greener Alternative Product

resistivity:

0.003-0.008 Ω-cm, thermally annealed 300 °C for 30 minutes, film thickness >100 nm, 25 °C

particle size:

≤3 μm

viscosity:

5-50 Pa.s(25 °C) (shear viscosity at 10 s-1)

bp:

213-218 °C (Terpineol)

density:

0.9-1.1 g/mL at 25 °C