934259

Ready-to-Cast Si Anode Slurry for Lithium ion battery

1-micron silicon particles

Manufacturer: Sigma Aldrich

Synonym(S): Ready-to-Cast Si Anode Slurry for Lithium ion battery, Silicon anode slurry

Select a Size

| Pack Size | SKU | Availability | Price |

|---|---|---|---|

| 25 ML | 934259-25-ML | In Stock | ₹ 20,415.95 |

934259 - 25 ML

In Stock

Quantity

1

Base Price: ₹ 20,415.95

GST (18%): ₹ 3,674.871

Total Price: ₹ 24,090.821

grade

battery grade

Quality Level

100

form

slurry

composition

Si (active material), >28 wt. % solids, 35-43 wt. %

color

dark gray to black

particle size

1 μm

application(s)

battery manufacturing

Description

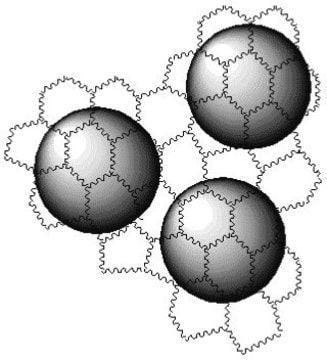

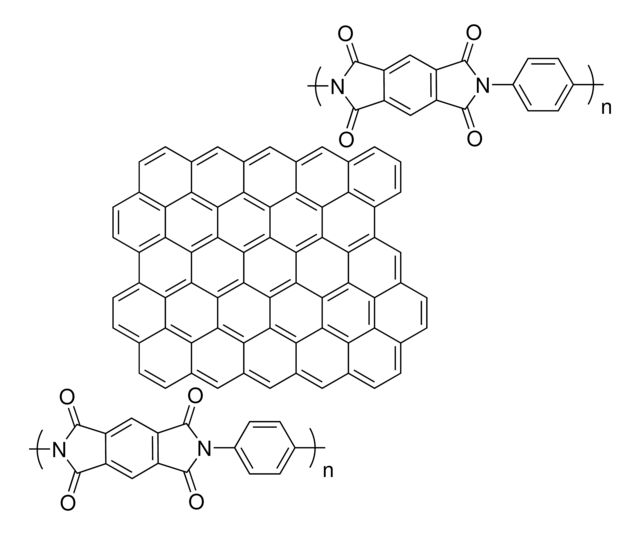

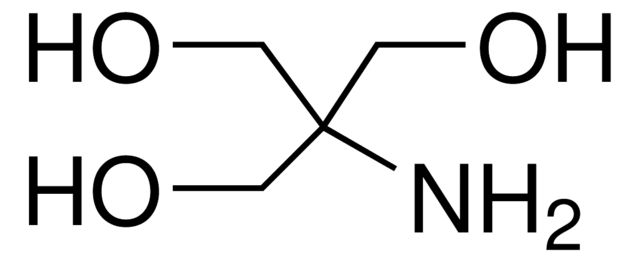

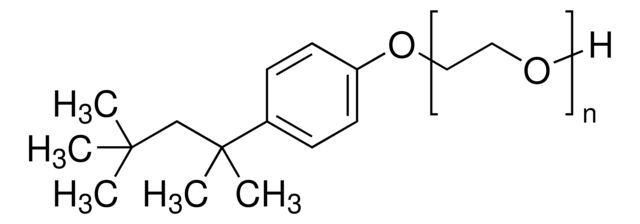

- General description: Our ready-to-cast silicon anode slurry is a liquid-type dispersion, composed of high-purity 1-micron sized silicon particles, conductive additives, binder (poly(acrylic acid)), and water. The product features a high silicon loading content and excellent stability, ensuring superior performance and uniformity in battery fabrication.

- Application: Our ready-to-cast silicon anode slurry is specifically designed to enable the production of high-performance silicon anodes for lithium-ion batteries. The slurry can be easily coated onto copper foil current collectors using blade-coating or slot-die coating techniques. Due to the precise formulation of our slurry, it is stable and processable, ensuring uniform and defect-free films of silicon anode material.The high silicon loading content and excellent stability of our ready-to-cast silicon anode slurry result in superior battery performance. Researchers can readily use our slurry to optimize their lithium-ion battery fabrication process, resulting in high-performance batteries suitable for a variety of applications.

SAFETY INFORMATION

Pictograms

Signal Word

Danger

Hazard Statements

Precautionary Statements

Hazard Classifications

Aquatic Chronic 3 - Eye Dam. 1

WGK

WGK 1