147230

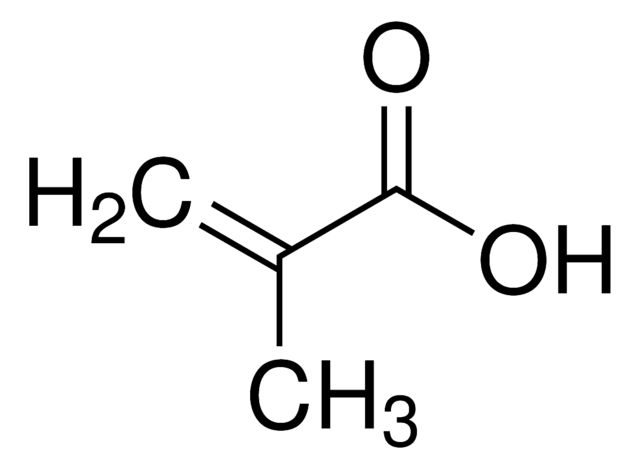

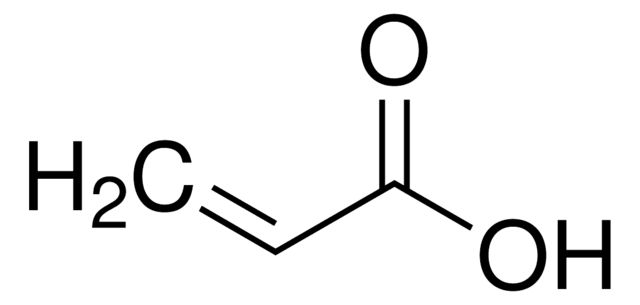

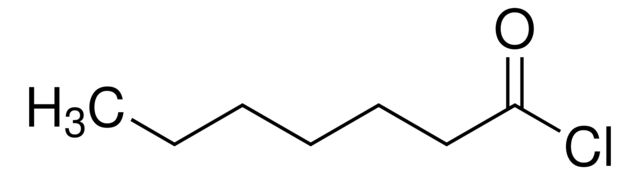

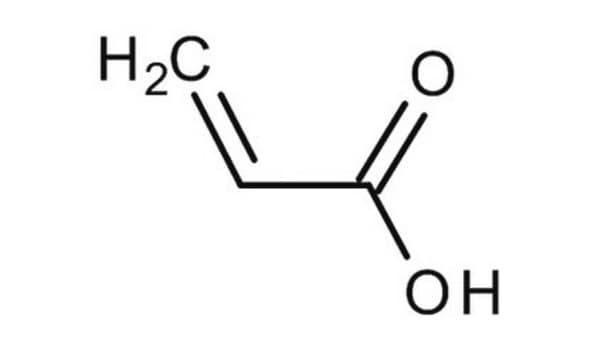

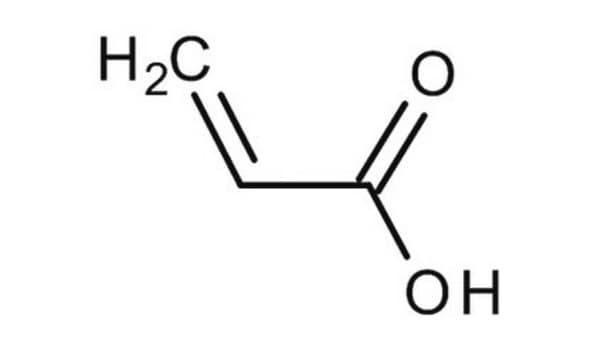

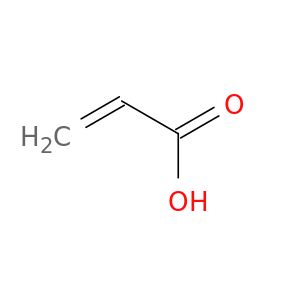

Acrylic acid

anhydrous, contains 200 ppm MEHQ as inhibitor, 99%

Manufacturer: Sigma Aldrich

CAS Number: 79-10-7

Synonym(S): 2-Propenoic acid

Select a Size

| Pack Size | SKU | Availability | Price |

|---|---|---|---|

| 500 G | 147230-500-G | In Stock | ₹ 3,041.83 |

| 5 G | 147230-5-G | In Stock | ₹ 3,745.45 |

| 100 G | 147230-100-G | In Stock | ₹ 4,589.80 |

| 1 L | 147230-1-L | In Stock | ₹ 7,923.90 |

| 3 KG | 147230-3-KG | In Stock | ₹ 9,190.43 |

| 2.5 L | 147230-2.5-L | In Stock | ₹ 13,206.50 |

| 18 KG | 147230-18-KG | In Stock | ₹ 44,847.98 |

147230 - 500 G

In Stock

Quantity

1

Base Price: ₹ 3,041.83

GST (18%): ₹ 547.529

Total Price: ₹ 3,589.359

grade

anhydrous

Quality Level

200300

vapor density

2.5 (vs air)

vapor pressure

4 mmHg ( 20 °C)

Assay

99%

form

liquid

autoignition temp.

744 °F

contains

200 ppm MEHQ as inhibitor

expl. lim.

13.7 %

bp

139 °C (lit.)

Other Options

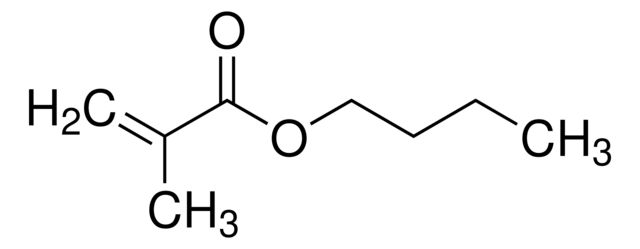

| Image | Product Name | Manufacturer | Price Range | |

|---|---|---|---|---|

| Acrylic acid | Sigma Aldrich | ₹ 6,379.99 - ₹ 54,840.00 | |

| Acrylic acid | Sigma Aldrich | ₹ 6,379.99 - ₹ 54,840.00 | |

| 79-10-7 | Acrylic acid | A2B Chem | ₹ 1,424.00 - ₹ 2,047.00 |

Description

- General description: Acrylic acid is an unsaturated carboxylic acid that is commonly used as a versatile building block in the chemical industry because of its reactive double bond between the carbon and oxygen atoms. It is used to prepare various acrylic acid-based polymers, which are used for various applications such as adhesives, paints & coatings, medical devices, organic semiconductors,thin-film transistors, hydrogels and lithium-ion batteries. Additionally, acrylic acid also serves as one of the polyelectrolytes in the self-assembled polymeric film used for hydrogen generation.[1][2][3]

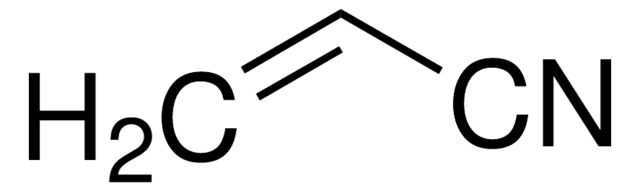

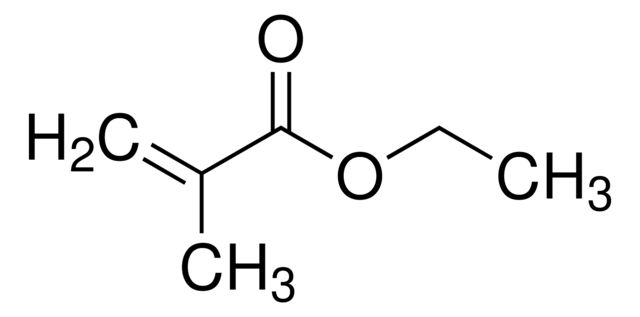

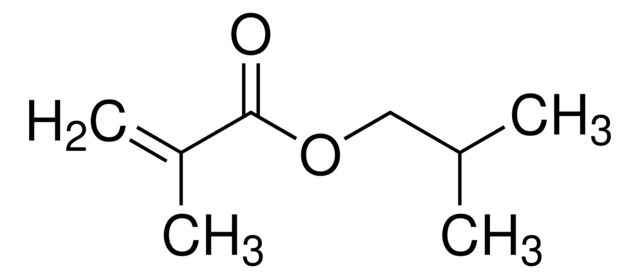

- Application: Acrylic acid can be primarily used as a monomer to produce various acrylic polymers, including polyacrylic acid, polymethyl methacrylate (PMMA), acrylonitrile butadiene styrene (ABS), and many others. These polymers exhibit a wide range of properties, such as transparency, scratch-resistant, flexibility, and resistance to water and chemicals, which make them valuable materials in various applications. Acrylic acid is also used as a key component in the synthesis of superabsorbent polymers(SAPs). These polymers possess a unique ability to quickly absorb and retain large quantities of water. Due to their excellent properties, SAPs have been widely used in many fields, such as drug-delivery systems, chemical industry, and personal care, etc. Acrylic acid can also be used as: A key component in the preparation of copolymer binder, which helps to optimize the performance of lithium-ion batteries.[4] A surface modifier for the carbon nanotubes with poly(acrylic acid) in order to improve adhesion and dispersion of the nanotubes in the oxide semiconductor matrix for thin-film transistor applications.[5]A reactive monomer for the surface modification of polydimethylsiloxane (PDMS)through a simultaneous polymerization process with ethylene glycol dimethacrylate. Modified PDMS potentially applied in new applications fields such as microfluidics or biomedical devices.[6]A precursor for the synthesis of cashew gum/acrylic acid nanoparticles via the copolymerization process. The use of acrylic acid in the synthesis is to introduce hydrophilic functional groups into the cashew gum backbone, thereby improving its solubility in water and increasing its compatibility with other hydrophilic materials.[7]AAc is used in preparing monodispersed poly (N-isopropylacryamide) (PNIPAM)/AAc microgels.[8] AAc has been plasma-deposited on surfaces for cell culture applications.[9] Surface modification of poly(ethylene terephthalate) (PET) films via UV-induced graft copolymerization with AAc has been reported.[2] AAc is used primarily as an intermediate in the production of acrylates.[10]

SAFETY INFORMATION

Pictograms

Signal Word

Danger

Hazard Statements

Precautionary Statements

P210 - P273 - P280 - P303 + P361 + P353 - P304 + P340 + P310 - P305 + P351 + P338

Hazard Classifications

Acute Tox. 4 Dermal - Acute Tox. 4 Inhalation - Acute Tox. 4 Oral - Aquatic Acute 1 - Aquatic Chronic 2 - Eye Dam. 1 - Flam. Liq. 3 - Skin Corr. 1A - STOT SE 3

Target Organs

Respiratory system

WGK

WGK 2

Personal Protective Equipment

dust mask type N95 (US), Eyeshields, Gloves