910716

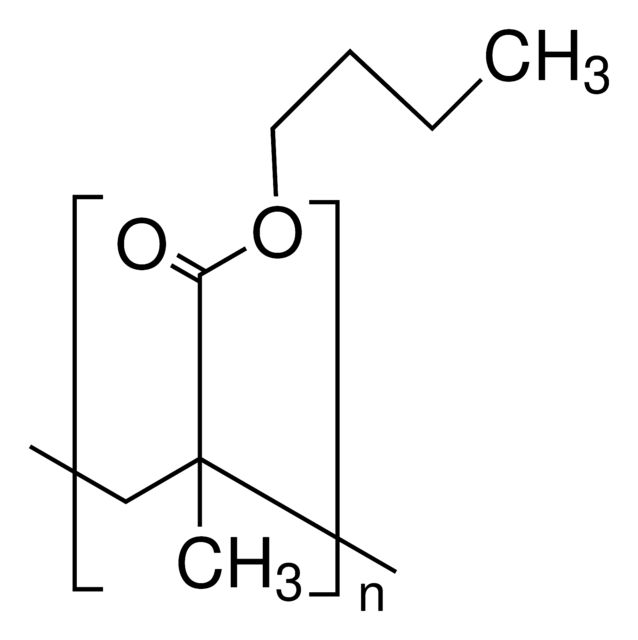

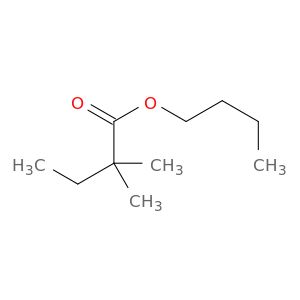

Poly(butyl methacrylate)

free flow beads, Mw 211,000

Manufacturer: Sigma Aldrich

CAS Number: 9003-63-8

Synonym(S): PBMA

Select a Size

| Pack Size | SKU | Availability | Price |

|---|---|---|---|

| 5 G | 910716-5-G | In Stock | ₹ 6,238.20 |

| 250 G | 910716-250-G | In Stock | ₹ 7,814.40 |

910716 - 5 G

In Stock

Quantity

1

Base Price: ₹ 6,238.20

GST (18%): ₹ 1,122.876

Total Price: ₹ 7,361.076

description

Brookfield Viscosity in 40% toluene: 500-800 cPsGlass transition temperature onset: 20 °CMaximum % Moisture: 0.30%

form

solid (bead)

mol wt

Mw 211,000

refractive index

n/D 1.483

density

1.07 g/mL at 25 °C (lit.)

InChI

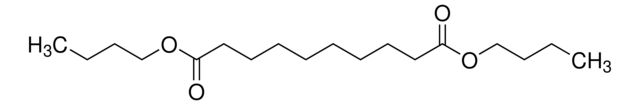

1S/C8H14O2/c1-4-5-6-10-8(9)7(2)3/h2,4-6H2,1,3H3

InChI key

SOGAXMICEFXMKE-UHFFFAOYSA-N

Other Options

| Image | Product Name | Manufacturer | Price Range | |

|---|---|---|---|---|

| 9003-63-8 | Poly(n-butyl methacrylate) | A2B Chem | ₹ 13,172.00 - ₹ 15,664.00 |

Related Products

Description

- General description: Additional Benefit:Conventional high molecular weight poly(butyl methacrylate) easily forms a fused block that require mechanical force (such as hammering) to break it down into small particles before usage. This product was developed with an anti-blocking technology and comes in an easy-to-use, free flowing, bead form.

- Application: Poly(butyl methacrylate) finds applications in various areas.It may be used to study the photoluminescence in EuTFC embedded in Poly(butyl methacrylate) (PBMA) polymer films.[1]It has also been used for coatings,[2][3] surface modification,[4] solid state battery, silk screen inks, adhesives for plastic and aluminum, plasticizer for hard butyl methacrylate resins, and for improving outdoor durability of vinyl chloride resins in pigmented lacquers.

- Preparation Note: How to Prepare Solutions:This polymer dissolves at room temperature but requires constant agitation to prevent solvent-swollen granules of polymer from forming agglomerates and sticking to the walls of the vessel. Important: The polymer beads should be sifted directly into the vortex of the stirred solvent to speed wetting-out and dispersion. Continuous low-shear agitation for periods of 1-12 hours, depending on the grade and concentration of resin, is recommended. After the solution appears clear in the tank, a sample should be spread out on a Leneta card or glass. After the solvent evaporates and a film forms on the card or glass, there should not be any resin seeds. If there are any seeds, the tank should be agitated further to fully dissolve the resin. Tank agitation should not be stopped (except for sampling) until the film test indicates there are no resin seeds. Any cloudiness or residue may indicate that some polymer remains undissolved. The presence of water in the system can also cause cloudiness. Solution time can be reduced by heating; most common solvents can be heated to approximately 49°C (120°F) without the need for reflux equipment. High-shear agitation also cuts dissolving time, but requires care to avoid overheating and excessive solvent loss.

SAFETY INFORMATION

Pictograms

Signal Word

Warning

Hazard Statements

Precautionary Statements

P261 - P272 - P280 - P302 + P352 - P333 + P313 - P362 + P364

Hazard Classifications

Skin Sens. 1

WGK

WGK 3

Flash Point(F)

Not applicable

Flash Point(C)

Not applicable

Compare Similar Items

Show Difference

description: Brookfield Viscosity in 40% toluene: 500-800 cPsGlass transition temperature onset: 20 °CMaximum % Moisture: 0.30%

form: solid (bead)

mol wt: Mw 211,000

refractive index: n/D 1.483

density: 1.07 g/mL at 25 °C (lit.)

InChI: 1S/C8H14O2/c1-4-5-6-10-8(9)7(2)3/h2,4-6H2,1,3H3

InChI key: SOGAXMICEFXMKE-UHFFFAOYSA-N

description:

Brookfield Viscosity in 40% toluene: 500-800 cPsGlass transition temperature onset: 20 °CMaximum % Moisture: 0.30%

form:

solid (bead)

mol wt:

Mw 211,000

refractive index:

n/D 1.483

density:

1.07 g/mL at 25 °C (lit.)

InChI:

1S/C8H14O2/c1-4-5-6-10-8(9)7(2)3/h2,4-6H2,1,3H3

InChI key:

SOGAXMICEFXMKE-UHFFFAOYSA-N